Reliable Winding Wires Manufacturer in India - A Smart Choice for Modern Industries

In India’s power-intensive economy, selecting the right winding wires manufacturer is crucial to ensuring the performance, safety, and durability of your electrical systems. Winding wires are the heart of motors, transformers, generators, and other electrical equipment—and quality directly affects functionality.

In the competitive landscape of electrical manufacturing, choosing the right winding wires manufacturer is not just about compliance with specifications; it is about fostering innovation and enhancing operational efficiencies. For instance, manufacturers who prioritize research and development are more likely to introduce cutting-edge technologies that significantly improve wire performance, such as enhanced insulation materials that withstand higher temperatures and reduce energy loss.

This comprehensive guide explains why choosing a trusted winding wires manufacturer in India is a business-critical decision and what factors to consider when sourcing from the Indian market.

Additionally, the reputation of a winding wires manufacturer plays a pivotal role in the decision-making process. Companies that have received industry awards or certifications, such as ISO or UL listings, often provide an added layer of assurance for buyers. These accolades not only demonstrate compliance with international standards but also reflect a commitment to quality and excellence.

What Are Winding Wires, and Why Do They Matter?

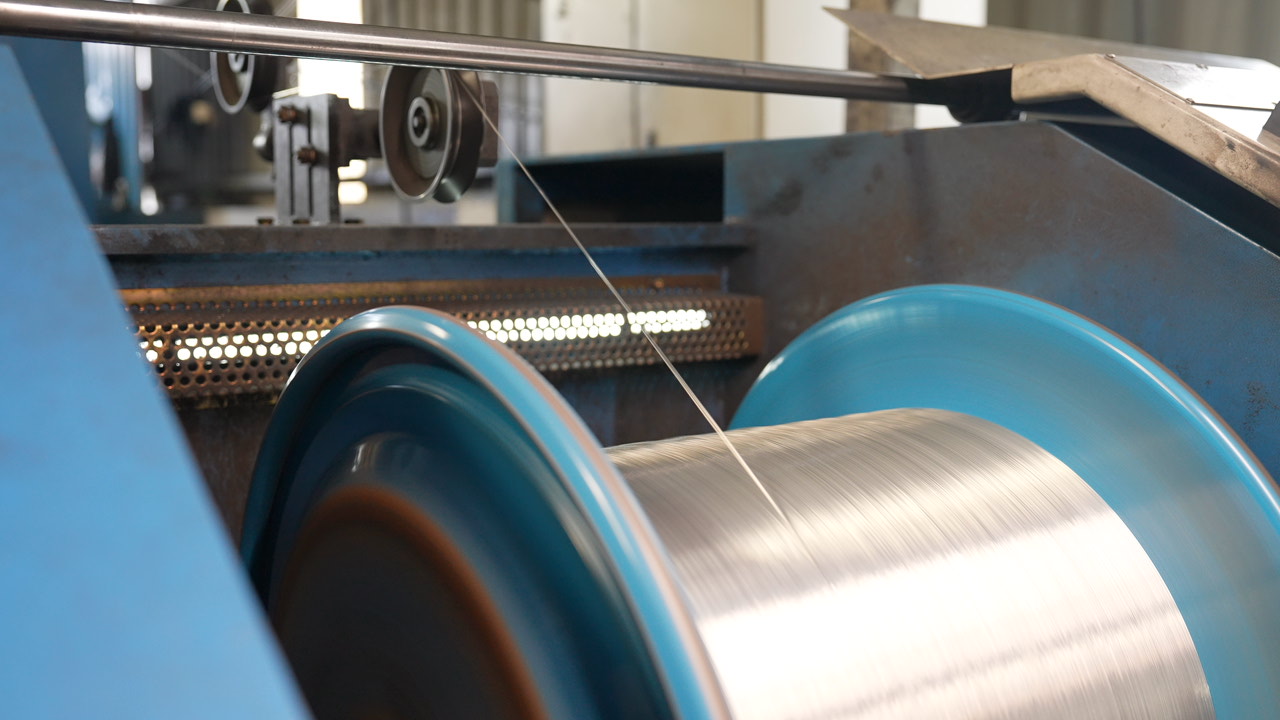

Winding wires are insulated conductors—commonly made of copper or aluminum—used in the winding of motors, transformers, and electromagnets. Their design ensures excellent conductivity, mechanical strength, and resistance to heat and chemical corrosion.

Moreover, the significance of winding wires extends beyond mere functionality; they also contribute to the overall efficiency of electrical systems. For example, high-quality winding wires minimize resistance and energy loss, which is especially critical in applications where performance is paramount, such as in electric vehicles or renewable energy systems, where efficiency translates directly into cost savings and sustainability.

A reliable winding wires manufacturer ensures consistent quality and helps reduce energy loss, equipment failure, and unnecessary downtime.

Key Factors to Consider When Selecting a Winding Wires Manufacturer

1. Material Purity

Leading manufacturers use 99.97% pure electrolytic copper or EC-grade aluminum. The purity impacts the wire’s conductivity and lifespan.

In practice, the choice of material can affect not only the electrical properties but also the mechanical properties of the wires. For instance, 99.97% pure electrolytic copper has a lower resistance compared to lesser grades, which leads to better heat dissipation and a longer lifespan of electrical components. The longevity of electrical systems directly correlates to the quality of the winding wires used, thereby influencing maintenance costs and downtime.

2. Insulation Technology

A quality winding wires manufacturer uses high-grade enamel coatings—like polyester, polyester-imide, or dual-coated enamel—for superior thermal class performance (B, F, H).

Furthermore, understanding the different insulation technologies can empower buyers to make informed decisions. Enamel coatings, for instance, come in various forms, each suited for specific applications. Polyester insulation, for example, is ideal for applications requiring high thermal endurance, while polyester-imide combines thermal performance with better adhesive properties, making it suitable for high-speed motors.

3. Dimensional Precision

Check for tolerance compliance with IS 13730/IEC 60317 standards. Accurate diameters reduce vibration and ensure tight winding, especially in high-speed applications.

Dimensional precision is critical not just for performance but also for compatibility with existing systems. When manufacturers adhere to standards like IS 13730 or IEC 60317, it ensures that components fit perfectly, reducing the likelihood of mechanical failure due to improper fit, which can be particularly detrimental in high-speed applications where vibrations are prevalent.

4. In-House Quality Testing

Trusted winding wires manufacturers in India conduct rigorous testing for:

Quality testing should encompass a series of rigorous assessments, such as thermal cycling tests that simulate real-world operational conditions. This kind of testing helps identify potential points of failure before the product reaches the market, thereby safeguarding both the manufacturer and the end-user from costly mistakes.

-

Breakdown voltage

-

Elongation

-

Pinholes

-

Adhesion and flexibility

5. Production Capacity and Lead Time

Choose a manufacturer that can meet your volume needs on time. Delays in electrical wire supply can stall large-scale industrial and infrastructure projects.

Applications of Winding Wires Across Indian Industries

Additionally, the versatility of winding wires allows them to be adapted for various applications, including specialized sectors such as aerospace and medical devices, where precision and compliance with stringent regulations are paramount. For example, in the aerospace industry, winding wires must withstand extreme conditions while maintaining integrity and performance, leading manufacturers to innovate continuously.

India’s fast-growing sectors like electric vehicles, renewable energy, railways, industrial automation, and consumer appliances all rely on high-quality winding wires. The demand for a trustworthy winding wires manufacturer has never been higher.

-

Transformers: Copper or aluminum winding wires used in distribution and power transformers

-

Motors: AC/DC motors for fans, pumps, EVs, and compressors

-

Generators: Compact and large-capacity winding for continuous duty

-

Appliances: Compressors, induction heaters, and microwave transformers

Why Indian Buyers Prefer Local Winding Wires Manufacturers

With the Indian government promoting Atmanirbhar Bharat, domestic manufacturers now offer competitive pricing, consistent quality, and faster logistics than imported alternatives.

The Atmanirbhar Bharat initiative not only encourages self-reliance but also fosters a culture of quality in Indian manufacturing. By prioritizing local manufacturers, buyers can influence the market towards better practices, thus ensuring a brighter future for the industry as a whole. This shift also means that local manufacturers are more attuned to the needs and preferences of Indian buyers, allowing for tailored solutions that meet specific market demands.

A local winding wires manufacturer offers:

-

Better communication

-

Local tech support

-

Cost-effective customization

-

Shorter lead times

You can expect high-grade products that meet both BIS and international benchmarks.

In today's market, sustainability is not just an option but a requirement. As environmental concerns grow, manufacturers are investing in technologies that not only comply with regulations but also enhance their marketability. For instance, using recyclable materials not only reduces waste but also appeals to a consumer base that increasingly values corporate responsibility.

Leading Indian winding wires manufacturers are moving toward sustainable operations—using low-emission processes, recyclable materials, and green packaging. Sustainability-conscious clients now look for suppliers with ISO 14001 environmental management systems.

Vidyametal: Trusted Winding Wires Manufacturer in India

Vidyametal’s commitment to quality is evidenced by the adoption of modern manufacturing techniques that enhance precision and reduce waste. Their approach ensures that they not only meet but exceed client expectations, establishing themselves as a leader in the winding wires market. Furthermore, their dedication to customer service facilitates a seamless purchasing experience, which is crucial in today's fast-paced business environment.

At Vidyametal, we are recognized as a dependable winding wires manufacturer for sectors ranging from power and automation to EV and HVAC. We deliver:

-

Wires in sizes from 0.12 mm to 4.5 mm

-

Class B, F, and H insulation

-

Options in both copper and aluminum

-

Customized wire lengths and packaging

-

Full technical data and test reports on request

Our modern facility in Gujarat supports fast dispatch across India and Southeast Asia.

Market Growth: Why It’s the Right Time to Choose an Indian Winding Wires Manufacturer

As India’s electrical wire and cable sector experiences this unprecedented growth trajectory, it presents an ideal opportunity for businesses to invest in local manufacturing. This shift not only reduces dependency on imports but also contributes to the local economy, creating jobs and fostering community development.

According to IEEMA, India’s electrical wire and cable sector is expected to grow at a CAGR of 12–15% over the next five years. Domestic manufacturers are now matching global standards in insulation technology, testing, and production capacity.

With the expanding capabilities of local manufacturers, sourcing high-quality winding wires has become more accessible than ever. By partnering with a reputable winding wires manufacturer, businesses can ensure that they are equipped with products that not only meet their specifications but also contribute positively to their operational efficiency and overall success.